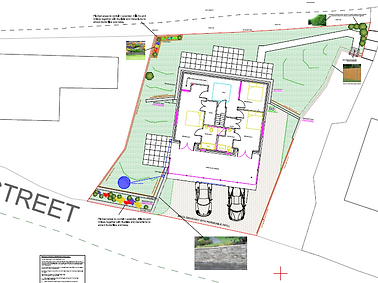

Argoed, Blackwood

Lark Engineering expertly handled the substructure and superstructure design for a new dwelling, incorporating a retaining wall that seamlessly integrated the building into the hillside. Close collaboration with building control and the architect ensured that the structure was positioned near the highway while maintaining compliance. The design features large glazed elements framed with robust steelwork, along with a lower ground garage nestled within the building. A thoughtfully designed mezzanine structure overlooks an open lounge, enhancing the home's spacious feel.

Welland Park Academy

Provided superstructure design for a multi-sports hall & changing rooms comprising of a steel portal frame spanning 18m with bracing in perpendicular direction. Cladding rails and purlins within rafter stays were utilised as secondary steelwork components. A total of 50tonnes of hot and cold-rolled steelwork was used to complete this project.

Land at Talywain

Superstructure and substructure design of two new dwellings at Talywain. Liaison with the local Geotechnical engineer confirmed sufficient ground conditions for a ground bearing strip solution supporting suspended beam and block flooring at ground (due to the presence of ground heave). Full height glazing supported by steel 'A' frames with steel ridge beams to allow a vaulted ceiling at first floor level.

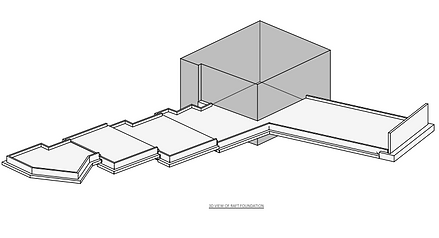

Upper Nelson

Following a review of the ground conditions by others, it was confirmed that a raft foundation was required for substructure of 7 new residential plots. A hollow block retaining wall was detailed and tied into two sides of the foundation to allow the finished floor level to sit lower than the highways.

Temporary Storage, Northampton

A temporary storage facility was required within an industrial space in Northampton. Lark Engineering provided superstructure design for two portalised units with plan bracing in one bay and K bracing for stability.

Oaklands

The client required a single-story rear extension, significant internal alterations and a loft conversion. Sub-structure was confirmed as a ground bearing strip following trial pit and existing foundation reviews on site with local Building Control. A reinforced suspended slab was designed to span from ground floor to first to allow the construction of a custom concrete spiral staircase. New steel ridge beams and rafters spanning from eaves to ridge were installed to allow the removal of existing trusses and open up the first floor.